THE SCIENCE BENEATH THE FLOOR

By Mike Niese, Vice President of Sales and R&D, Robbins Sports Surfaces

Prior to the late 1980s, the sports flooring industry was a scene more akin to the Wild West, with manufacturers quick to tout material performance “data” derived from isolated material-based lab tests. These tests lacked both standardization and relevance to real-world athlete performance, measuring parameters like how deeply a rubber pad indents or compresses under pressure, and results were often presented as indicators of resilience and athlete safety. But there was no meaningful science connecting what was being measured and the effects on the human body when interacting with the floor.

This was the state of the industry when Robbins Sports Surfaces decided to take a different path grounded in science, not marketing hype. We weren’t satisfied with knowing how a floor performed in a vacuum. Learning what happens to an athlete’s musculoskeletal structure during interaction with a floor is much more important than understanding what happens to a floor system when impacted by an athlete. That decision and change in direction has made all the difference.

From the DIN Standard to Biomechanics

In 1987, we initiated a collaboration with the Otto-Graf-Institute (Stuttgart, Germany) and began working with the Deutsches Institut für Normung (DIN) to explore what were then the most comprehensive material-based standards in the world. We developed half a dozen floor systems that met all the criteria outlined in DIN standards, a first for the U.S. market, and in doing so, began the industry’s first real attempt at standardized performance values for sports floors.

However, the DIN tests, while more rigorous than anything in the U.S. at the time, were still quite limited. These tests were based on impact forces generated by a 150-pound “simulated athlete.” And while useful for evaluating certain material properties, they told us nothing about what actually happens within an athlete’s musculoskeletal structure when they make contact with the floor. And so, at Robbins, we took our commitment to athlete safety and performance one step further.

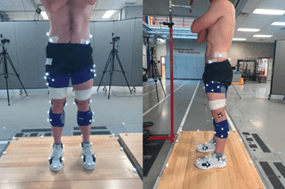

Starting in the early 1990s, we began working closely with the University of Calgary and renowned kinesiologist/ bio mechanist Dr. Benno Nigg. Together, we launched a series of studies designed to analyze the human side of athletes interacting with a sports floor system; specifically, the effects on joints, muscle groups, fatigue, injury risk and overall biomechanics. This was not marketing, it was research. The same kind of deep, peer-reviewed, university-backed research that still sets us apart today.

The Birth of MVPTM Technology: Engineering for Performance

The culmination of years of biomechanical research came in the form of one of our most groundbreaking products: MVP (Maximum Vibration Protection). Developed in 1997 and fully launched in 2005 after extensive testing and refinement, the MVP system represented a major departure from traditional sports floor engineering.

Dr. Nigg’s research on the MVP system revealed something extraordinary. The MVP behaved unlike any floor previously researched. Specifically, it demonstrated unique vibration control, damping vibration and aftershock within milliseconds. In engineering terms, we were approaching “critical damping,” a property that dramatically reduces the energy transferred into an athlete’s body, lowering fatigue and mitigating injury risk.

This vibration control wasn’t accidental, it was the result of deliberate design. At the time, the MVP’s understructure was so different in appearance from other flooring systems that our own sales team had doubts that it would sell. But the data didn’t lie. As we like to say, “Feeling is Believing.” And once we understood what the system could do for athlete health and performance, there was no turning back.

Unimax100®: Enhanced Technology for Every Athlete

As we continued our biomechanical investigations, we realized something else: while MVP was ideal for high-performance use in the NBA and elite collegiate programs, the market could benefit from a modification of the technology refined for the broader range of athlete body types, mass and play styles. This led to the development of Unimax100, a sister product to MVP that delivers high-level biomechanical performance with a design that is more responsive across a wider spectrum of body structures and masses.

Unlike MVP, which uses a two-layer plywood structure, Unimax100 relies on a single-layer plywood structure. This slight variation has significant implications. Unimax100 reacts more quickly to a broader range of impact forces and provides a biomechanical advantage that particularly benefits smaller mass and female athletes by taking into account anatomical differences such as hip structure and center of gravity, items no other manufacturer in the industry is currently addressing.

Unimax100 doesn’t replace MVP, it complements it. MVP remains the premiere system for NBA-level play and other elite programs. But for mixed-use gyms, university and high school athletics, as well as programs with diverse athlete populations, Unimax100 delivers biomechanical responsiveness and performance that’s second to none.

From Research to Real-World Results

Our commitment to science-based testing isn’t confined to the lab. We’ve taken our technology and applied it in real-world environments, and the results speak volumes.

Take our collaboration with several premier NCAA teams. After installing an MVP floor in their practice facilities, teams are reporting up to 30% reduction in injuries. This is a staggering statistic in an industry where having only a few percentage points of improvement is considered significant. In one case, a player who had previously experienced pain from a fractured metatarsal was able to train pain-free on the MVP court, specifically because of its superior vibration containment.

With the massive success of MVP, along with the rapidly building success of the UniMax100 system, we are currently seeking other applications of MVP technology in other specialty type floors.

Biomechanics vs. Materials: A New Standard

At Robbins, we still test to DIN and other material-based standards like MFMA (Maple Flooring Manufacturers Association) PUR test standards because the market expects it. But to be clear, those tests are not the measure of athlete performance. They indicate how a floor reacts to impact, but not how that impact affects the athlete.

The quality, performance and success of our biomechanically designed and researched systems, MVP, UniMax100 and All-Star Portable products, have gained attention among elite basketball programs, including a professional player-safety focused group. Our collaboration with these groups unites their innate knowledge of athletes’ musculoskeletal structures with our distinct knowledge of floor systems and biomechanics, bringing heightened awareness and understanding of the relationship between and importance of biomechanics, floor design and player safety. This is the science of real-world interactions between athletes and flooring equipment.

This collaboration signals a major shift. It’s not about just passing lab tests. Instead, our focus is improving lives, extending careers and giving every athlete a safer foundation on which to compete.

The Path Forward

As an industry, we are at a crossroads. Material-based standards are being watered down, making them easier to meet while the tests that truly matter such as field tests, biomechanical evaluations and vibration properties are largely not understood or simply ignored. The ASTM (American Society for Testing and Materials) test standards, the test protocol for MFMA PUR, acknowledge that area deflection is a meaningful proxy for vibration damping, yet the market still leans toward metrics that are simpler to pass.

We believe it’s time for a change.

Our top systems, MVP and Unimax100, are already overdesigned in the best way possible. They deliver unequaled biomechanical performance, unparalleled uniformity and unmatched stability, culminating in the industry’s highest performance floors with the best game-play characteristics. They’re engineered to provide many decades of high-impact use, equaling or outlasting the longevity of other systems offered in the market. And now, with glue-down options, we’re enhancing floor uniformity and gameplay response, extending the floor longevity and improving biomechanical performance, all while reducing workers’ exposure to concrete dust, a serious OSHA (Occupational Safety and Health Administration) concern.

Conclusion

Other companies may talk about athlete and performer safety. At Robbins, we’ve been investing in the science to prove it for over four decades. From biomechanics to vibration control to floor uniformity, from elite NBA arenas to high school gyms, dance studios and volleyball courts, we design every floor with one question in mind: What does this mean for the athlete or performer? The same science that protects a basketball player’s knees also safeguards a dancer’s joints and a volleyball player’s landing. Because every movement matters.

Robbins was the first in North America to adopt the DIN standards, long before the rest of the industry even recognized their value. We didn’t just follow the guidelines; we engineered floor systems specifically to meet and exceed them, then introduced those innovations to the market. As expected, the competition followed. While others focused solely on materials-based compliance, Robbins advanced into the realm of biomechanics, partnering with leading researchers to understand how floor systems impact the athlete, not just the floor. We pioneered vibration control, muscle response analysis and damping behavior long before these concepts entered mainstream industry dialogue. Today, others mimic the language and retrofit their products to appear aligned, but without doing the scientific work behind it. At Robbins, we don’t wait for the industry to tell us what matters. We define it.

If the answer doesn’t start and end with science, it’s not a Robbins floor.

Studying Athlete Movement Forces on Different Surfaces – University of Calgary Human Performance Lab

About the Expert

Mike Niese is the Vice President of Sales and R&D at Robbins Sports Surfaces. He has close to 25 patents in his name, having spent over 50 years in the sports flooring industry pioneering the development and application of biomechanical testing and performance standards for athlete safety and optimization.